- Sustainability Report 2023-2024

- Environmental information

Policies, targets and actions

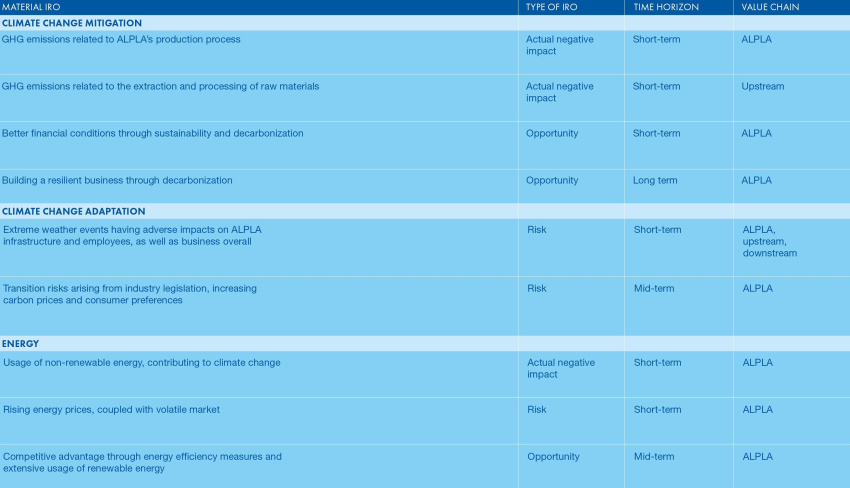

ALPLA’s Sustainability Statement reflects our commitment to the three pillars of sustainability: People (employee engagement and society), Planet (production and environment) and Profitability (economy and governance). Guided by a set of principles and measurable targets, we ensure that ALPLA ‘reflects sustainability in our actions’, as outlined in our Global Strategy 2026.

Our standalone ALPLA Group policy for energy presents our principles in terms of energy management overall, including our adherence to ISO 50001 requirements and our continuous focus on energy conservation and thus GHG emissions reduction.

Climate change is undeniably one of the greatest challenges facing our society. As a global leader in manufacturing rigid plastic packaging, ALPLA recognises its role and impact in this context. A thriving business cannot exist in a compromised ecosystem, which makes climate change an existential threat to our operations. We fully understand and embrace our responsibility to contribute to mitigating its effects.

In addressing climate change, we actively reduce our carbon footprint not only through enhanced energy efficiency, but also the adoption of renewable energy sources and the transition to post-consumer recycled raw materials. Additionally, we prioritise production either directly at customer sites (in-house facilities) or in close proximity to them (nearby facilities) to minimise emissions and conserve resources.

Our decarbonisation journey

ALPLA’s commitment to decarbonisation was firmly demonstrated by its decision to join the Science Based Targets initiative (SBTi) in June 2022. In August 2024, SBTi approved ALPLA’s near-term targets which align with the Paris Agreement’s goal of limiting global warming to 1.5°C. These targets cover Scope 2 and Scope 3 emissions and are supported by a comprehensive decarbonisation road map developed through to 2030, approved by ALPLA’s Sustainability Steering Council in May 2024. This road map identifies key decarbonisation levers and models their respective impacts.

Scope 2 emissions reduction

ALPLA has committed to reducing Scope 2 emissions by 42% by 2030, using 2021 as the baseline. The strategy is built on two primary decarbonisation levers applicable to our operations worldwide:

Transition to renewable electricity

A major focus for ALPLA has been switching to renewable electricity through on-site photovoltaic systems and external procurement via power purchase agreements (PPAs) and energy attribute certificates (EACs). In 2024, all ALPLA base and recycling plants in Germany, the UK, Turkey and Brazil transitioned to at least 95% renewable electricity. ALPLA prioritises expanding renewable electricity use by balancing economic feasibility, market maturity, local legislation and customer demand. Collaboration with key customers which share similar sustainability goals plays a crucial role in scaling these efforts.- Energy efficiency improvements

ALPLA conducts annual energy assessments at five to six production sites to identify high-potential energy-saving projects. These assessments analyse energy consumption and efficiency, leading to tailored action plans for each site. The savings potential per assessment averages around 10%, driven by modernisation efforts and investments in new systems and machinery. Most of the energy efficiency improvements are linked to cooling activities (49%) and production machine improvements (24%).

Scope 3 emissions reduction

Scope 3 emissions, primarily driven by ALPLA’s value chain, represent a significant opportunity for decarbonisation. ALPLA aims to reduce emissions from purchased goods and services and processing of sold products by 51.6% per tonne of procured raw materials by 2030 (from a 2021 baseline). Four global strategies support this goal:

- Increased use of post-consumer recycled (PCR) materials

As a signatory of the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment, ALPLA is aiming for 25% PCR raw materials by 2025. This shift has a substantial impact as PCR materials can reduce product carbon footprints by up to 90% compared to virgin materials. In 2024, the share of PCR raw materials in our portfolio was 22%, up by 2 percentage points from 2023.

- Expansion of recycling capacity

ALPLA continues to scale its recycling operations, aiming to double its PET and HDPE installed and projected mechanical recycling output capacity from 350,000 tonnes in 2023 to 700,000 tonnes by 2030. This strategy reduces exposure to volatile market conditions and strengthens ALPLA’s competitive advantage.

- Focus on circular-economy principles

ALPLA promotes the principles of the 4Rs of the circular economy beyond ‘recycling’ as well. Lightweighting projects (‘reduce’), reusable packaging development (‘reuse’) and investments in bio-based and biodegradable materials (‘replace’) are integral to its innovation strategy.

- Collaboration across the value chain

ALPLA recognises the importance of working closely with customers and suppliers to achieve its decarbonisation goals. Customers play a crucial role in adopting product-level sustainability initiatives, while suppliers provide low-carbon raw materials critical for meeting Scope 3 targets. Accordingly, in 2024, we integrated sustainability into our procurement processes and started to actively support our key suppliers in their own sustainability journeys by setting sustainability-related expectations for them.

By 2030, ALPLA anticipates significant changes in its raw material portfolio. Virgin materials will remain dominant but are expected to decrease by at least a quarter compared to 2021. Meanwhile, recycled materials, especially internally produced ones, will see substantial growth.

Our targets and current performance against them are depicted in the table below:

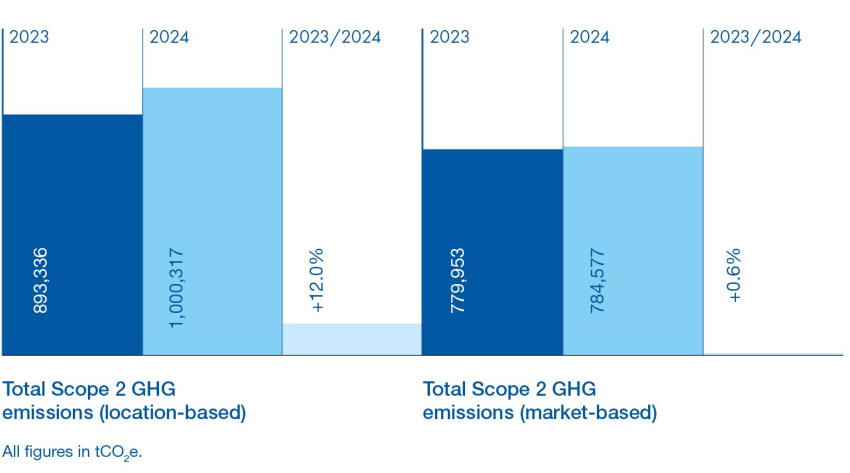

Despite our best efforts to expand the usage of renewable electricity across our operations, our Scope 2 GHG emissions stagnated during the reporting period and were 18.5% higher in 2024 than in the baseline year, suggesting that an even more concentrated effort is needed to achieve our 2030 target. (For more information on electricity consumption and related Scope 2 GHG emissions, please refer to the Metrics section.)

On the other hand, we slightly decreased our Scope 3 intensity target over the reporting period and reached a total of 15.2% drop compared to the baseline year, enabled by a continuous shift towards recycled materials in our portfolio.

Climate change adaptation – physical climate risks

Operating 200 manufacturing plants across 47 countries, we are acutely aware of the impact climate change has on ALPLA. From recent windstorms in Argentina and hurricanes in Mexico to severe flooding in Spain, we are constantly reminded of the critical importance of climate change adaptation.

In 2024, we initiated the development of a qualitative physical climate risk assessment. After identifying potentially relevant climate hazards, we employed a twofold approach: first, we conducted desktop research using the GPS coordinates of our plants to assess theoretical exposure to various climate hazards. Second, we launched an internal questionnaire to gather local insights on actual exposure and historical impacts.

This approach allowed us to establish a baseline and identify the most appropriate adaptation strategies for addressing critical climate risks. Moving forward, we will continue refining these solutions to meet specific local needs and minimise the adverse effects of climate hazards on our operations.

We outline below the most significant physical climate hazards impacting ALPLA, along with the corresponding planned adaptation measures.

![]()

Heat waves are a significant climate hazard for ALPLA, affecting over one-third of our plants. These heat waves impact our employee health and safety, operating facilities, production equipment and, occasionally, our water supplies. To mitigate these vulnerabilities, we are currently in the process of installing air conditioning units, dehumidifiers and heat extractors at selected plants.

![]()

Heavy precipitation and storms also impact our plants, affecting 43% and 32% of our plants respectively. We have incurred harm to buildings, supplies, site accessibility and delivery commitments. Maintenance of roofs and drainage systems, well-defined emergency plans and the installation of backup power supplies have been effective adaptation measures against these events.

Flooding hazards affect 15% of our plants, with issues ranging from disruptions to raw material supply to damage to production equipment and buildings. Consequently, we are improving our drainage systems, weather systems and emergency plans.

![]()

Cold snaps are a climate hazard for ALPLA with 9% of plants reporting vulnerabilities. Impacts include disruptions to supply chains and power supply; health and safety concerns; and facility damage. Our resilience measures include upgrading heating systems and improving building insulation.

Water stress has not been identified as a significant climate hazard currently impacting ALPLA’s business, but exposure to it is increasing. According to our 2024 assessment, nearly 40% of ALPLA production facilities are in areas with at least a high risk of water stress. Under the pessimistic RCP 8.5 scenario, this figure could rise to 53% by 2080, suggesting that exposure may translate to impact in the near future.

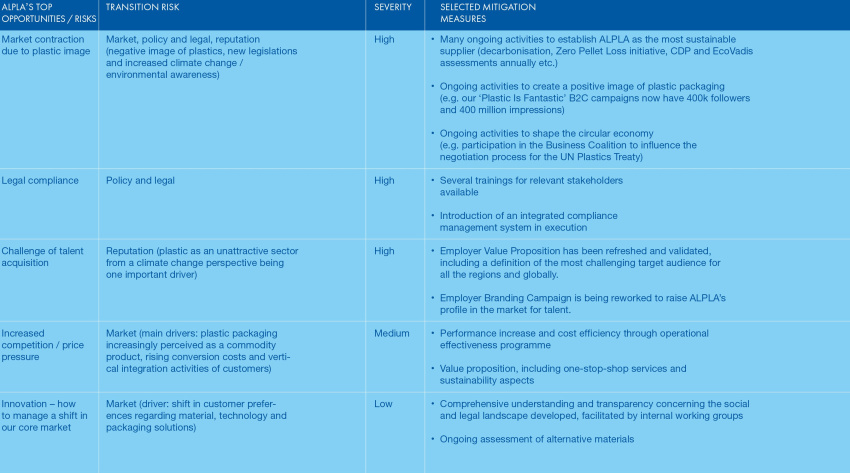

Climate change adaptation – transition climate risks

The strategic chance and risk management (ChaRM) process at ALPLA is a comprehensive framework designed to identify, manage and monitor strategic risks and opportunities. The ChaRM process involves regular updates and evaluations to address emerging risks and opportunities, including transition risks such as market contractions due to the negative image of plastics, new legislation and increased environmental awareness. By proactively managing these transition risks, ALPLA aims to protect its reputation, minimise financial loss and enhance decision-making capabilities.

In the latest ChaRM cycle (2019-2024), 125 strategic opportunities and/or risks were identified. Out of these, 56 were grouped into ALPLA’s top five risks. The table below presents them and assesses them from a transition risk perspective.

Metrics

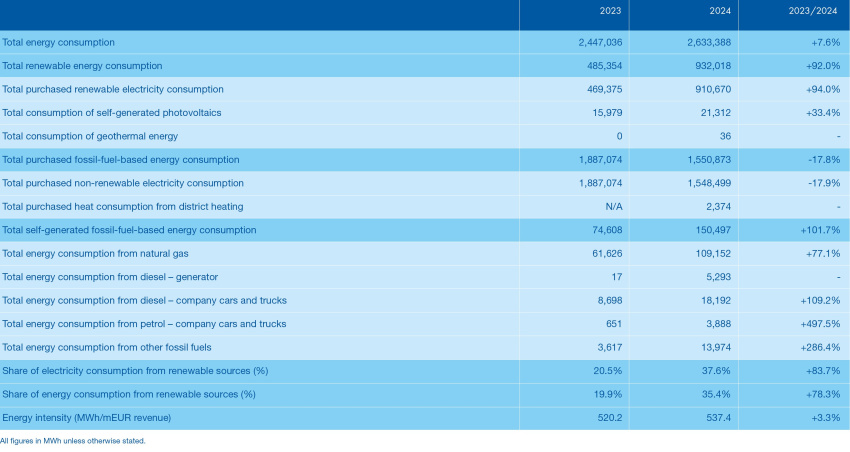

Energy consumption

In 2024, ALPLA reported total energy consumption of 2.6 million MWh, marking a 7.6% increase compared to the previous year. Energy intensity rose year on year by 3.2%, from 521 to 537 MWh/mEUR revenue. These increases can be attributed to higher production volumes, improved data collection practices and a broader coverage in data reported by adding a set of fossil fuel types such as heating oil, propane, kerosene, paraffin and LPG.

Of the total energy consumption in 2024, 94.2% was electricity, underscoring the electricity-intensive nature of our production processes. The small share of directly consumed fossil fuels provides a strong lever for reducing carbon emissions by transitioning further towards renewable electricity sources.

Renewable energy consumption

In 2024, electricity from renewable sources – resulting from certified purchased electricity consumption and self-generated electricity consumption – accounted for 37.6% of our overall electricity consumption. This marks a significant increase from 20.5% in 2023 and reflects an improvement of 17.1 percentage points in just one year.

ALPLA base and recycling plants in six countries — Austria, Brazil, Germany, Portugal, Turkey and the UK — operated on more than 95% renewable electricity in 2024. The WEEU region recorded the highest increase in its renewable electricity share, more than doubling its consumption volume year on year. Key drivers for this improvement include large-scale transitions to renewable electricity in Portugal, Spain, the UK and Germany as well as almost tripling photovoltaic (PV) self-generation from 1,500 MWh to nearly 4,500 MWh. Globally, the gross electricity generated from photovoltaics increased by 33.4% from 2023 to 2024.

Non-renewable energy consumption

In 2024, ALPLA’s non-renewable energy consumption reached approximately 1.7 million MWh and represented 64.6% of total energy use, down from 80.2% in 2023. The vast majority (91.0%) came from electricity purchased from national grids. While grid electricity often includes a renewable component, ALPLA applies a conservative reporting method by classifying all electricity consumption as non-renewable unless it is backed by energy attribute certificates (EACs).

Direct fossil fuel use, primarily of natural gas, diesel and petrol, made up the remaining 9.0% of non-renewable energy and 5.7% of total energy consumption in 2024. Although comparatively small, fossil fuels thus remain relevant, especially natural gas which is the feedstock in combined heat and power (CHP) systems to generate electricity and is also used at some locations for heating and industrial processes. Total self-generated fossil-fuel-based energy consumption more than doubled year on year, which is explained by increased natural gas usage in our CHP systems and improved data collection which now covers smaller energy sources.

Energy efficiency

The year-on-year global energy efficiency improvement reached 0.84% in 2023 and 0.73% in 2024. With 38.4% of total energy consumption occurring at ISO 50001-certified plants, energy efficiency is subject to systematic analysis and continuous improvement within ALPLA.

GHG emissions

We recognise that our operations contribute to the global carbon footprint. To address this, we quantify the greenhouse gas (GHG) emissions associated with our plastic packaging and recycling production each year. Our metric, CO2e, encompasses not only carbon dioxide but also other relevant greenhouse gases and converts them into carbon dioxide equivalents based on their climate impact.

Our emissions calculation provides a holistic view of our carbon impact by including direct emissions from owned or controlled sources (Scope 1), indirect emissions from purchased electricity (Scope 2) and all relevant indirect emissions arising from activities across our value chain (Scope 3, both upstream and downstream).

ALPLA employs an operational-control approach to calculate GHG emissions. This methodology ensures we account for emissions from activities under ALPLA’s operational control and offers a comprehensive representation of our carbon footprint.

Our calculations follow the internationally recognised Greenhouse Gas Protocol (GHG Protocol) standards, which provide robust methodologies for measuring and reporting GHG emissions. By adhering to the GHG Protocol, we ensure that our reporting is consistent, transparent and credible, enabling stakeholders to reliably evaluate our progress in reducing emissions.

As part of our commitment to continuously improving the accuracy of our carbon footprint calculations, we are incorporating an increasing amount of primary data into our assessments. This enhancement required adjustments to the methodology for certain emission sources, and they are presented below transparently for each category concerned.

ALPLA’s overall global GHG emissions increased by 6.1% year-on-year, from 7.4 to 7.8 million tCO2e, primarily driven by the biggest contributor, Scope 3. Below we present the details of our GHG emissions per scope. We then elaborate on our detailed methodological approach to GHG emissions at the end of this chapter.

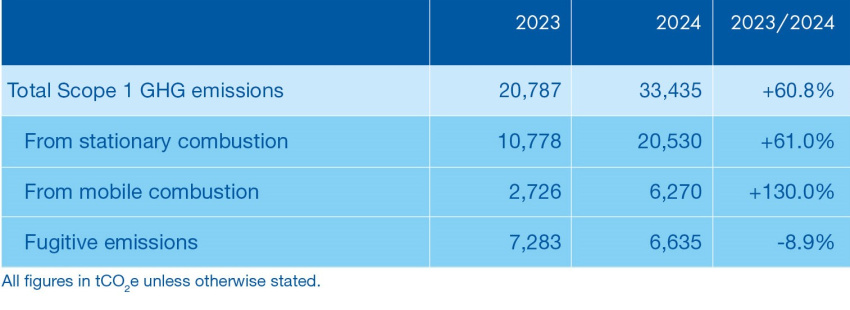

Scope 1 (direct emissions)

Scope 1 accounts for less than 0.5% of ALPLA’s total GHG emissions and arises from fuel combustion in owned or leased assets under ALPLA’s operational control. In 2024, we enhanced data collection by incorporating new data points and standardising definitions for existing ones, ensuring a more comprehensive assessment. This resulted in emissions being more than 60% higher than 2023.

Stationary combustion accounted for 6.1% of all Scope 1 GHG emissions in 2024, with natural gas usage being by far the main source of emissions. It also accounts for the majority of the year-on-year increase, with considerably higher natural gas consumption in our CHP systems in 2024.

Mobile combustion also increased, driven primarily by a more comprehensive data collection process. On the other hand, less fugitive emissions were reported in 2024 compared to 2023, resulting from the refills of our chillers globally.

Scope 2 (indirect emissions from purchased electricity)

Scope 2 emissions represent the second-largest source of ALPLA’s carbon footprint, accounting for approximately 10% of our total GHG emissions in both reporting periods (market-based approach).

Despite our substantial increase of renewable electricity usage across our operations (explained further in the Energy section), our market-based GHG emissions stagnated. This can be explained by two main factors: firstly, we consumed more than 100,000 MWh more electricity year on year, reflecting our continuous business expansion. Secondly, the externality resulting from consistent use of the most recent IEA database for location-based emission factors had a considerable impact on our GHG emissions: just by adhering to the latest database, we witnessed a 7% increase in our location-based GHG emissions. As the most recent IEA database was influenced by the turbulent year that 2022 was, we are confident that this external factor will in the longer term support our decarbonisation efforts, since the share of renewable energy in the global energy mix is expected to increase significantly in the coming years.

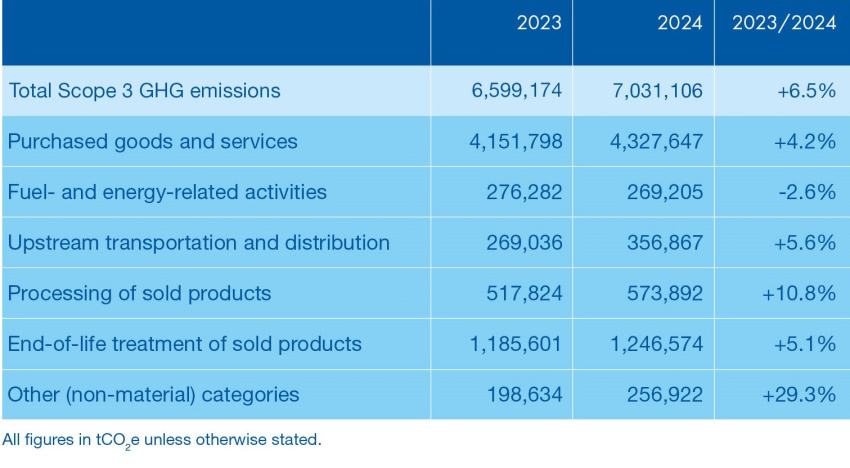

Scope 3 (indirect emissions from value chain)

Emissions arising from our value chain are by far the largest contributor to our overall business carbon footprint (with a roughly 90% share both years). Within Scope 3, Category 1 (purchased goods and services) is the dominant emission source as it comprises our purchased raw materials.

Our global expansion clearly made a mark on our Scope 3 emissions: apart from some smaller categories, all Scope 3 categories increased year on year, contributing to an overall 6.5% increase.

Methodological approach related to GHG emissions accounting

Scope 1 emissions relevant to ALPLA are categorised into three sub-categories:

- Stationary combustion is the largest source of Scope 1 emissions, including emissions from fuel combustion at ALPLA plants for electricity generation, heating and steam production. The calculations account for the combustion of a wide variety of fuels, including natural gas (the predominant fuel used), heating oil, propane, diesel, kerosene, paraffin and LPG, with primary data collected internally. Emission factors are sourced from the most current IEA emission factor database.

- Mobile combustion emissions result from fuel combustion in vehicles operationally controlled by ALPLA, including road vehicles (cars, vans, trucks) and private jets. Prior to 2024, the fuel use data for these vehicles was only estimated; however, data collection processes have since been adopted to close this gap. Road vehicle emissions are calculated using primary fuel consumption data multiplied by the IEA’s direct combustion emission factors. Jet emissions are determined using the GHG Protocol’s Mobile Combustion v2.6 tool based on primary fuel consumption data.

- Fugitive emissions refer to the unintentional leakage of greenhouse gases from production processes and equipment. For ALPLA, the primary source is refrigerant leakage, particularly from chillers. Other smaller sources, such as dryers and air conditioning units in plants and offices, are excluded due to their negligible impact and the resource-intensive nature of data collection. The emission factors used are the 2021 IPCC (AR6) Global Warming Potential factors.

- In line with the operational-control approach, only purchased electricity is included in the calculation. This means that electricity consumption at in-house plants where ALPLA does not bear the cost is excluded from the scope to prevent double counting. Activity data is collected internally and covers all ALPLA plants within the reporting boundary.

- In our calculations, we use the most recent IEA location-based electricity emission factors. In addition, we calculate the market-based emission factors by considering the use of renewable electricity – self-generated (solar) and purchased – and this electricity is tracked through separate data collection. It includes regionally procured energy attribute certificates (EACs) and power purchase agreements (PPAs).

When accounting for Scope 2 GHG emissions, the following considerations were taken into account:

- In line with the operational-control approach, only purchased electricity is included in the calculation. This means that electricity consumption at in-house plants where ALPLA does not bear the cost is excluded from the scope to prevent double counting. Activity data is collected internally and covers all ALPLA plants within the reporting boundary.

- In our calculations, we use the most recent IEA location-based electricity emission factors. In addition, we calculate the market-based emission factors by considering the use of renewable electricity – self-generated (solar) and purchased – and this electricity is tracked through separate data collection. It includes regionally procured energy attribute certificates (EACs) and power purchase agreements (PPAs).

In 2021, we developed our first comprehensive Scope 3 GHG emissions inventory and have since focused on continuously improving data quality. In both reporting periods, five categories accounted for more than 95% of our Scope 3 emissions. The methodological approach to them is detailed below. For the other non-material categories, we used a combination of calculations and high-level estimations.

- Scope 3.1: purchased goods and services include all purchased raw materials as well as dyes and additives. We used the average-data method, calculating emissions based on the quantities of various materials purchased with ALPLA’s data. We did not include raw materials sourced internally (i.e. rPET and rHDPE from our recycling plants) and PET/rPET volumes under the ‘hard tolling’ scheme (where customers pay for and transport the raw materials). However, the input materials for our recycling plants (PET and HDPE bales) were included in the calculation. For emission factors, we relied on the most recent Ecoinvent 3.11 figures, with an aim of applying supplier-specific emission factors wherever available from next year onwards.

- Scope 3.3: fuel- and energy-related activities cover the extraction, production and transportation of fuels used to generate electricity. Emissions are calculated using the same electricity consumption data as Scope 2, with emission factors sourced from the most recent IEA emission factor database for upstream emissions related to electricity. Other energy sources were not included in the quantification due to their negligible impact.

- Scope 3.4: upstream transportation and distribution covers emissions from inbound as well as outbound transportation paid for by ALPLA. We applied the distance-based method, calculating emissions based on the transportation mode and distance (in tonne-kilometres) travelled. While we have granular data on outbound transportation to customers (except for our Pharma and Recycling divisions), we partially rely on estimates for the distance that purchased materials travel to our plants. We are continuously collaborating with key suppliers to transition to primary data for improved accuracy.

- Scope 3.10: processing of sold products includes emissions from blowing and bottling (filling, labelling, assembling) activities performed at customer sites. We used primary activity data (product volumes delivered to customers categorised by raw material and location, only excluding produced caps) alongside secondary IEA data to estimate related emissions.

- Scope 3.12: end-of-life treatment of sold products refers to GHG emissions from the management of the waste generated by the products we manufacture. We used the same primary activity data as for Scope 3.10 alongside secondary OECD data to estimate related emissions.